The Eventuri RSQ3 intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. We use 100% pre-preg carbon fiber with no fibreglass which means we can achieve a smooth internal surface to maintain smoother airflow. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

-

Carbon Fiber Patented Venturi Filter Housing with 103mm Outlet

-

Bespoke High Flow Dry Cone Filter

-

Carbon Fiber Inlet Duct

-

Carbon Fiber Tube with 103mm ID

-

Heat Shield with Gold Reflective Backing

-

Laser Cut Stainless Steel Brackets

-

Silicon Breather Hose

-

Silicon Couplers and Reducer

Patented Venturi Filter Housing Assembly

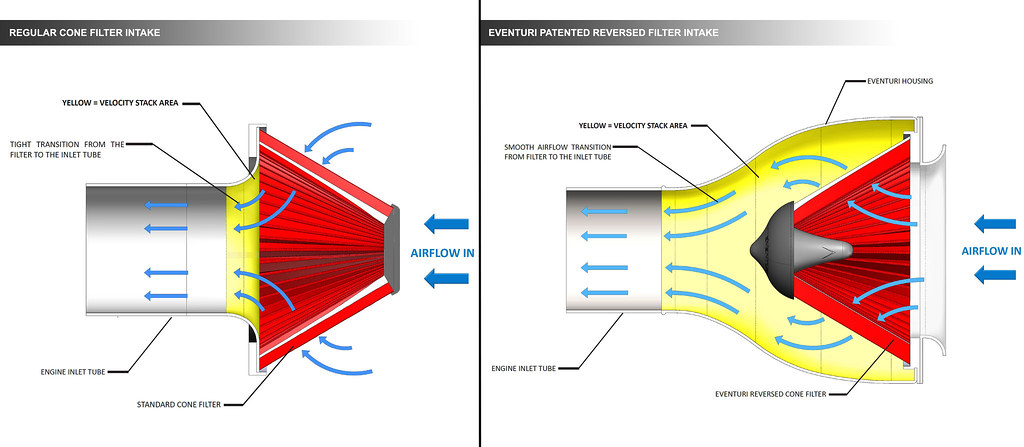

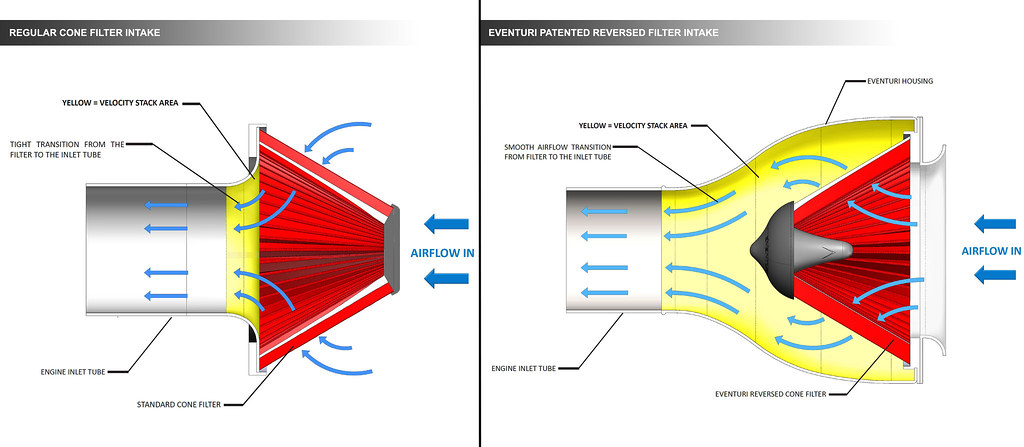

The Stage 3 filter housing comprises of a bespoke high flow filter, aluminium cowl, laser cut brackets and the carbon pod itself. The carbon pod shrouds the reverse mounted filter and smoothly shape the airflow down to the intake tubes. This smooth reduction in cross sectional area invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack - below is a diagram to show the comparison between our patented design and a regular intake system. Further details can be read in the Technology page.

Bespoke Stage 3 Cone Filter

In order to achieve the highest flow rate possible we had to redesign our stage 2 filter and increase the size to as large as was possible withing the RS3 engine bay area. The resulting filter has an outside diameter of 210mm or 8.3" and when flow tested with just the carbon housing is able to flow up to 940 CFM at 28" H2O. The filter medium is ISO tested to ensure that filtration is in line with OEM standards and is also dry. The filter is constructed with our signature flow cones to aid in the Venturi housing principle.

Carbon Fiber Intake Duct

The duct channels ambient air from the slam panel area to the filter housing. It fits inside the OEM ducting system and smoothly transitions to the circular filter housing shape. In order to ensure a good seal against engine bay heat - it also has a flexible rubber edging around the opening which presses against the filter housings creating the desired seal yet allowing the housing to move with the engine. Since this was designed to support high power builds, we found that the stock openings in the slam panel could cause a restriction at high flow demand. So we lifted the top surface of the duct and created an opening above the slam panel which is able to draw in cold air from behind the hood shut. This extra opening is equivalent to a hole with a diameter of over 7" and completely derestricts the stock cold air feed. The stage 3 duct was designed to have the maximum internal volume possible within the given geometry of the engine bay. This ensures that the filter housing is able to draw with minimum restriction.

We also made sure that the stage 3 duct is compatible with larger aftermarket throttle bodies.

Carbon Fiber Intake Tube

The intake tube is crafted from 100% prepreg carbon fiber and so as mentioned the internal surface is smooth and the carbon weave can be seen. The stage 3 tube has an internal diameter of 103mm or 4" and has a smoooth curvature to minimise pressure drop. It channels airflow from the Venturi housing to the turbo inlet. The smooth bend geometry ensures laminar flow is maintained from the filters to the exits.

Heat Shield

Due to the intense heat generated by the turbo, we designed a heat shield to protect the carbon tube. The shield is powder coated black but has a gold reflective layer on the base which deflects radiation heat from the turbo and catalyst. It has a stainless steel brace to provide rigidity and curves around the back of the tube to deflect convective heat away. Please note - this shield may not fit some full frame turbo systems with a different exhaust manifold.