This complete ignition system is designed to replace the factory pencil style coils which are prone to failure and incapable of properly supporting the needs of high horsepower applications. The kits all come complete with new ignition coils designed in house and manufactured to our specifications based on the needs and capability of the N54 engine.

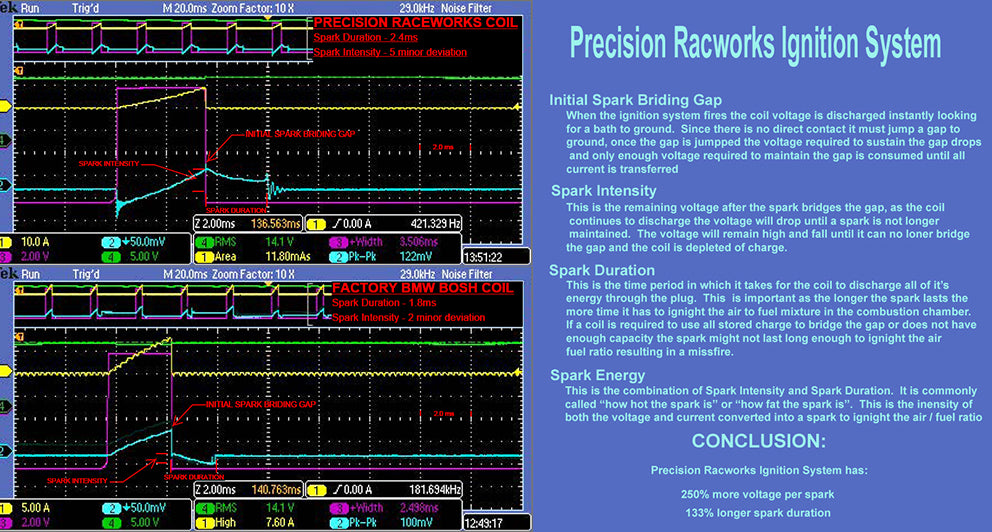

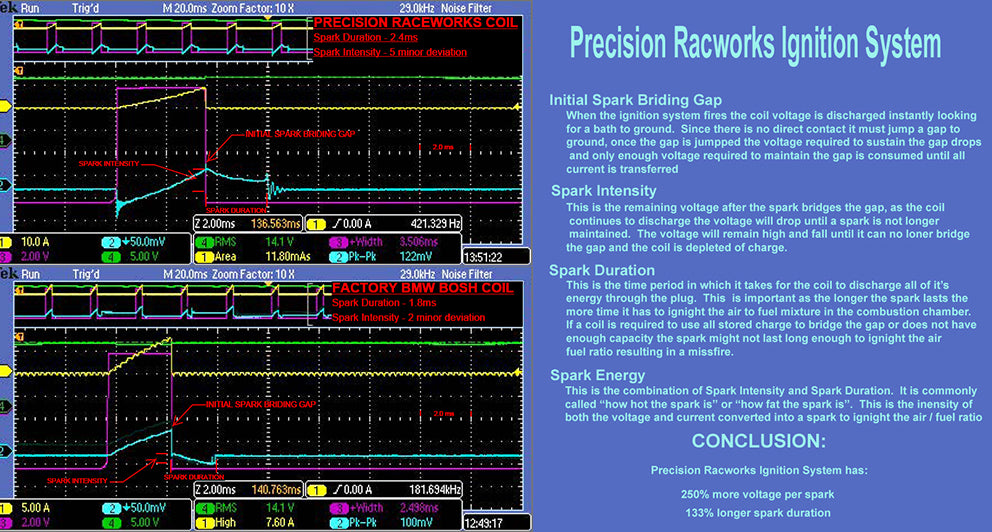

Before now the only solutions for the N54 community were all pencil style coils which are incapable (due to size limitations) of producing the same output as larger Ignition Block style coils. To make the best of the small package the pencil coil has, they are designed for high voltage output but very low current output. This means the spark will bridge the gap on the spark plug and then disappear. There is no duration to the spark and in the event the fuel does not ignite (or ignite fully) in that very short period of time you will have a misfire or incomplete burn.

Please Note:

For the OEM location kit, the ignitions coils will not be relocated.

The Aftermarket Manifold location kit is designed for relocation of the ignition coils onto aftermarket inlets.

For the relocation kit on the OEM manifold side, you will need the PR N55 BMW Ignition Kit

Click to Enlarge

Because of the constraint of space to put components in a pencil coil reliable and proven ACDelco ignition coils (PN D585 / LS Truck Coils) paired with short plug wires are used in high horsepower applications everywhere. So why didn’t we just make a kit using these coils since they are the “standard” in many high horsepower applications?

- Your car is specifically designed to run “Dumb Coils” and the ACDelco coils are “Smart Coils”

This leaves four options for adapting the car to work with them

-

Remove the factory DME and replace with Standalone system

- Very costly & you lose some factory functions

-

Remove the factory DME and change circuitry of the board to control “Smart Coils” instead of “Dumb Coils”

- Not a plug and play solution you can do at home, requires sending off your factory DME for custom work

-

Add additional electronics to convert the IGBT output from the factory DME back to 5V square wave to drive the “Smart Coils”

- The factory system only has 1 IGBT system that can fail this solution has two IGBT systems that can fail, plus an additional converter box that can fail as well. This results in 3 possible failure points. In addition the DME no longer can “see” the coils which could cause other potential problems with how the computer is designed to monitor and react.

-

Use the IGBT negative output and constant power with resistor to drive the IGBT inside the "smart coil" backwards

- As above the factory system only has 1 IGBT system that can fail this solution has two IGBT systems that can fail, plus a resistor which heats up and can fail as well. This results in 3 possible failure points. In addition the DME no longer can “see” the coils which could cause other potential problems with how the computer is designed to monitor and react.

- Flashing of the DME to suppress errors caused by using "Smart Coils" in place of "Dumb Coils" is required

- During testing of this approach it was found that the ignition coil produced about 1/2 of its original capability

- Testing also showed an increased stress on the IGBT in the coils increasing the failure rate and overall longevity of the coil

- The ideal dwell time (calculated based on Duty cycle, RPM, and Duration) plays a big role in selecting the right ignition coil in any application

The maximum dwell time of 3.5ms is a fixed value for the N54 engine (allowing headroom for built motors turning more RPM)

-

The ACDelco coil has an ideal dwell time of close to 4.5ms

- Since the ACDelco coil would only be allowed a maximum charge time of 3.5ms the output is greatly reduced to 90mj while the Precision Raceworks coil is capable of 118mj

So not only as explained above using a “SmartCoil” isn’t a great idea on the N54 as it is not designed for it you also need to consider the ideal dwell time allowed by the car and the design of the coil when making the proper selection. We have also included the quick reference chart below to better understand performance of the LS coil, OEM coil, PR coil,and for fun Lamborghini coil. Showing that there is no standard each coil is designed to work within specific calculated dwell periods so the correct coil must be selected or designed for each application.

Why choose Precision Raceworks?

By designing our own coil we were able to take into account the available dwell time of the N54 as well as the IGBT system being built into the DME. We were even able to take into consideration the ohm load of the factory BMW coil that came in the N54. What this means is our coil looks exactly like the factory coil to the DMEmaintaining all functions allowing the computer to monitor and react as designed by the engineers at BMW.

So these coils have 250% more output than the factory coils what does that mean for my DME as they are already prone to heat issues and component failures?

- Output is directly related to input current and time so let’s look at the math below using the given information from the chart above. We will use saturation dwell as this is the maximum output (the hardest the coil can work)

BMW Coil - 7.425amps / 2.7ms dwell = 2.75a per ms

PR Coil - 9.045amps / 3.7ms dwell = 2.44a per ms

For additional information we have provided the ACDelco and Lamborghini as well to see how they would react and load our system.

ACDelco Coil – 6.75amps / 5ms dwell = 1.35a per ms

*Lamborghini Coil - 16.2amps / 2.5ms dwell = 6.48a per ms

*This would result in 236% more strain on our electrical system if used requiring upgrades to other components to be stable

- So as you can see while the PR coil pulls more current to have higher output it is capable of doing it over a longer period resulting in less load on the electrical system.